A new scientific discovery that takes algae and turns it into crude oil in minutes rather than millions of years could be the end of constant worries over “peak oil.”

Engineers at the Department of Energy’s Pacific Northwest National Laboratory (PNNL) announced that they have created a process that takes an enriched stew of algae and turns it into crude oil which, in turn, can be made into a usable bio-fuel. The development was announced in a recent issue of the journal Algal Research.

Genifuel Corp., a biofuels company from Utah, has licensed the technology and is attempting to utilize the process on a larger, industrial scale.

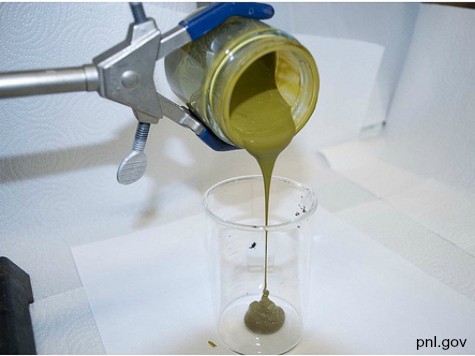

In a press release, PNNL described, “In the PNNL process, a slurry of wet algae is pumped into the front end of a chemical reactor. Once the system is up and running, out comes crude oil in less than an hour, along with water and a byproduct stream of material containing phosphorus that can be recycled to grow more algae.”

The press release also noted that “conventional refining” is then capable of taking the man-made crude oil and turning it into usable biofuels. PNNL notes that the man-made crude can be made into “aviation fuel, gasoline, or diesel fuel.”

PNNL also feels that its process has eliminated the high cost of other algae-based biofuels processes.

“Cost is the big roadblock for algae-based fuel,” said Douglas Elliott, leader of the PNNL research team. “We believe that the process we’ve created will help make algae biofuels much more economical.”

The biggest cost-saving aspect of the new process is that the PNNL team figured out how to use wet algae, whereas most other formulas require the algae to be in a dry form.

“Not having to dry the algae is a big win in this process; that cuts the cost a great deal. Then there are bonuses, like being able to extract usable gas from the water and then recycle the remaining water and nutrients to help grow more algae, which further reduces costs,” Elliot said.

Another exciting development in this new process is that the system works continuously. Other attempts created biofuels in single batches, but this new process works more like an assembly line in a continuously moving and producing system.

The new process also dispenses with the use of toxic chemicals and solvents to separate the energy-rich oils from the algae. The process uses high heat and pressure instead.

“It’s a bit like using a pressure cooker, only the pressures and temperatures we use are much higher,” Elliott said. “In a sense, we are duplicating the process in the Earth that converted algae into oil over the course of millions of years. We’re just doing it much, much faster.”

Perhaps it won’t be long before humanity manufacturing its own oil eliminates the question of whether to drill the earth for it.

COMMENTS

Please let us know if you're having issues with commenting.