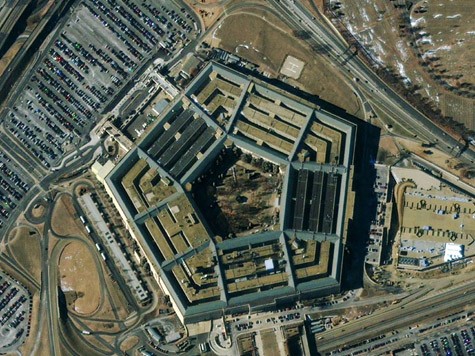

It is true and widely known that the US military readiness rests on outdated planes, vehicles, and parts. Severe budget problems affect all sectors of spending, and the military is usually often hit hardest despite a huge annual Pentagon defense budget. To meet its demands, the Pentagon has increasingly turned to cheaper and often unreliable foreign parts and weapons technology. The consequence of course impacts high-end prime US contracting companies that are forced to seek foreign markets to maintain revenue even if some of their oversea clients and partners are considered war adversaries. The trend toward foreign suppliers has only increased in recent years. The Defense Department recently revealed that an estimated 80 percent of all defense components are bought from foreign countries.

This happens despite regulations that encourage the Defense Department to buy American products. The problem though is that American made defense products and weapons technology are dwindling. The myriad regulations and policies make it impossible for the American private sector to produce the vital materials needed for modern weaponry.

The National Defense Magazine notes the domestic defense industry gap and the risks associated with defense outsourcing

China, for example, produces about 97 percent of rare earth materials — not so much because the country has most of the resources, although it does — but because most of the Western world, including the United States, stopped production for cost reasons. Russia is the world’s largest producer of titanium, an indispensable component in aircraft. Russia is also one of the world’s biggest producers of cobalt, a key component in aircraft engines, along with Canada and Australia, Cuba and several countries in Africa. The United States doesn’t produce any of its own cobalt.

The risks to national security are clear. The use of foreign suppliers and concern about the decline of the U.S. defense industrial base has been on the radar among some for years. As far back as 2003, this magazine noted that “The U.S. is becoming dependent on countries such as China, India, Russia, France and Germany for critical weapons technology. It is conceivable that one of these governments could tell its local suppliers not to sell critical components to the United States because they do not agree with U. S. foreign policy.”

That last point was experienced during the Iraq war when the military ran out of precision bombs. Boeing was forced to turn to Swiss companies for increased production, but because of the Swiss government’s disagreement with the Iraq war, they withheld key parts that slowed the production of precision bombs by months.

What prevents China’s government from infiltrating America’s national security systems through the use of Chinese businesses that America uses for high-end technology? The answer to that question goes without saying, they will and have. In order for foreign engineers to design and construct electronics and weapon parts, there is a great deal that needs to be shared. This necessarily causes the US to relinquish control on the design, quality inspection, and most importantly, secrecy. As a result, the US military constantly deals with defected and malfunctioning parts not to mention malicious technology embedded to exploit and possibly extract sensitive data vital to national security.

What this amounts to is China is being paid to possibly sabotage American defense while gaining access to technology that helps build their growing military.

Alan Tonelson Washington Times:

…the Senate Armed Services Committee has once again just reminded Americans that counterfeit imported electronics parts have been “flooding” into major U.S. military systems for years. Following up November hearings, a May 21 report by the panel described how, in 2009 and 2010 alone, staff found more than 1 million individual “suspect” parts bound for use or actually installed in several types of military aircraft, and even in the Pentagon’s anti-ballistic missile systems. More than 70 percent of those suspect parts were traceable to China. Moreover, such counterfeiting has been public knowledge since being spotlighted in a Commerce Department report released in January 2010.

The best data available indicate just how alarmingly America’s vulnerability has grown. U.S. Business and Industry Council research shows that as of 2010, products from China controlled nearly 28 percent of the total U.S. market for a huge group of civilian electronic components widely used in U.S. defense goods. This Chinese market share has roughly tripled since 1997. Chinese import penetration rates are nearly as high and also surging in categories such as printed circuits, printed circuit assemblies, resistors, transformers and broadcast and wireless communications equipment.

Have the new armed services findings finally awakened Washington? Fixes enacted last December include increasing inspections and tests of imported electronics parts; banishing unreliable companies from defense supply chains; requiring prompt reporting of counterfeits by contractors; and forcing defense firms to pay for replacing fakes.

But these measures remain dwarfed by the policy failure that originally shredded the supply chain’s integrity: outsourcing-focused trade policy decisions since the early 1990s that, with the enthusiastic support of major defense contractors and big technology companies, have sent much advanced U.S. electronics production to China.

As long as U.S. companies can supply lucrative American civilian and defense customers from very low cost, highly subsidized, regulation- and tax-free Chinese production sites in particular, the Pentagon will remain dangerously dependent on a country that’s anything but friendly and whose systemically secretive, cronyist business practices can frustrate even the most intrusive – i.e. unrealistic – monitoring and inspection programs.

COMMENTS

Please let us know if you're having issues with commenting.